Many domestic cardboard or paperboard manufacturers have five- or seven-tier corrugated board production lines, but companies that own these advanced equipment account for only a small part of the country's enterprises. Most carton manufacturers are affected by the market and funds. With technical restrictions, it is impossible to update advanced equipment at one time, and still retain single-sided machines, even using a single unit to produce cartons (cardboard). Therefore, how to further improve the quality of single-sided machined paperboard and reduce production costs is a common concern for these carton manufacturers.

Let's discuss the most direct and effective way to reduce production costs.

First, make full use of corner materials. At present, some companies have adopted the method of ordering paper in order to reduce the waste of corners. Of course, this method is preferable for the stable carton size, small variety, and large batch production volume; but for companies with various carton sizes and small production volumes, such an approach will inevitably lead to greater waste. The general strategy is to purchase all raw materials with a uniform width (1600mm). If a five-layer cardboard is produced, the longitudinal slitting specifications and the amount of materials may be reasonably calculated according to the specifications of the cardboard, and the remaining material of the corners may be used as a splice core. To give a few examples:

Cardboard width 590mm, production of five five-layer cardboard, then, the paper can be cut 500 knife, longitudinal slit into two 590mm, a 400mm. The core paper is cut into 250 knives, cut into two pieces of 590mm vertically and two pieces of 200mm. When gluing, 400mm and 200mm are spliced into 500 pieces of sandwich.

The width of the paperboard is 700mm, and 1000 sheets of five-layer paperboard are produced. Then, 500 papers can be cut in the paper and cut into two 700mm lengths and one 180mm lengthwise. The core paper was slashed with 389 knives, in which 167 knives were longitudinally slit into two 700 mm, one 180 mm, and 222 knives were longitudinally slit into three 530 mm. When silicone is used, 180mm and 530mm are combined into 666 cores.

Note: Any size of cardboard, as long as more than 10mm can be fully utilized, of course, the remaining material is only 10mm below the waste. It is worth noting that the large or small heads of the splicing must have 10 mm of exposed tile (in the operation of a single-sided machine, the bottom and the ends of the cardboard can be staggered by 10 mm). In silicone, the large head and small head must overlap 10mm. The overlapping part can only be within 10mm of the shiva, and it can only be a two-piece joint. When calculating, try to stagger the indentation line. In this way, neither the exposed tissue marks nor the vertical compressive strength of the cardboard will be affected. If it is a three-layer paperboard, the excess scrap can be rewinded by manual rewinding, and then the flanging can be carried out when the five-layer cardboard is produced.

Second, reduce the cost of adhesives. With a single-sided machine to produce corrugated cardboard, adhesives are the most critical. To reduce the cost of adhesives, first choose the lower cost starch adhesive. In the type of starch adhesive, a strong adhesive and a small amount of adhesive are selected. In general, the cost of composite adhesives (commonly known as cooked glue) can be controlled at about three cents per square meter of five-layer cardboard.

EnglishEspañolPortuguêsDeutschहिंदी日本語ខ្មែរNederlandsالعربية한국어मराठीMalagasyItalianoPolskiSvenskaελληνικάPусскийภาษาไทยTürkShqipMagyarViệtSamoaМонголMaltiIndonesia FrançaisMelayuҚазақшаYorùbáবাঙালিעִברִיתGàidhligSomaliEesti keelKreyòl Ayisyennorskčeštinaفارسیతెలుగుမြန်မာBosanskiMaoriქართულიRomânăбеларускіУкраїнськаతమిళGaeilgeSuomalainenپښتوລາວհայերենSlovenščinaFilipinoO'zbekÍslenskaייִדישLatviešuGalegoFryskनेपालीKurdîCatalàбългарскиHawaiianHrvatskiਪੰਜਾਬੀWong JawaKiswahililëtzebuergeschisiXhosaEuskalSundaZuluગુજરાતીТоҷикӣ

- Casa

- Chi siamo

-

Elenco prodotti

- Linea ondulata

- Macchina ondulata >

-

Ricambi a macchina ondulata >

- Giunto rotante

- Pettine per il marcatore di scivolone

- Pastiglie dei freni

- Pompa diaframma per colla

- Stripper di carta scarica

- Chuck di espansione

- Tubo flessibile in metallo

- Mola

- Nastro per splicer

- Rullo ondulato

- Lama di taglio

- Cintura di trazione del ponte sopraelevato

- Ruota del sole

- Cintura del trasportatore

- Lama da taglio NC

- Trappola a vapore

- Cilindri pneumatici

- Freno pneumatico

- Air Bellow Spring

- Pompa a vuoto ad anello d'acqua

- Lubrificante a macchina ondulata

- Distanziatore di gomma

- Distanziatore placcato in titanio

- Flexo Stampter Slotter

- Macchina della stampante Flexo >

-

Parti di ricambio della stampante >

- piastra di rame

- PIASTRA DI STAMPARE

- Pompa Aro.

- Pennello in acciaio e ottone

- Filtro in inchiostro

- Doctor Blades.

- Copertura dell'antico

- Lama di slotting.

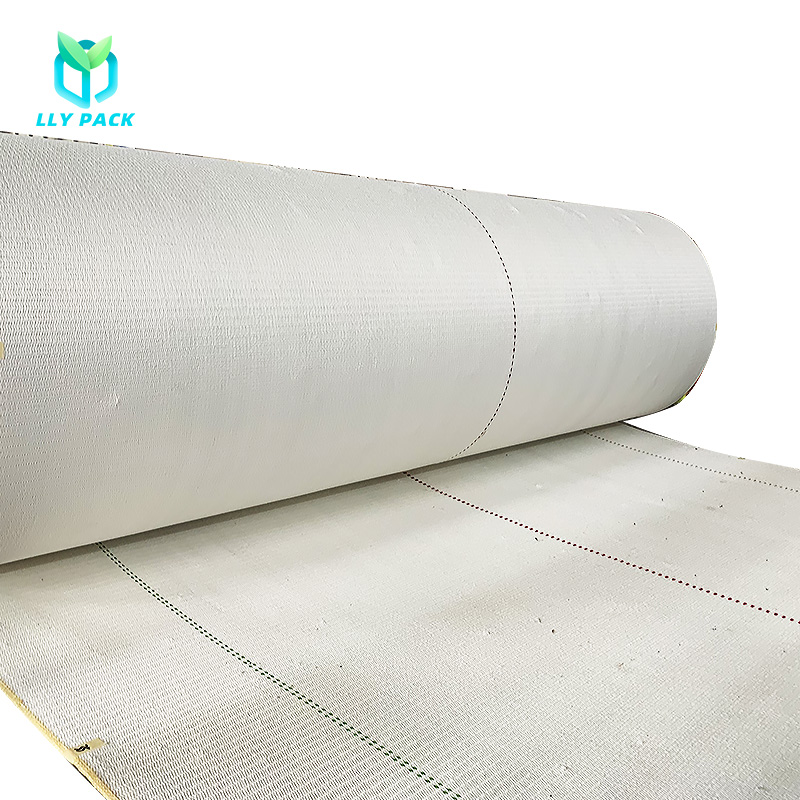

- Nastro in fibra

- Cornice sospesa

- PET PRESSIONE PET con film

- Cuscino di stampa r e bak

- Ruota di alimentazione

- Un modo portante

- Die board rotary.

- Pompa a diaframma singola

- Blocco finale con condotto a inchiostro

- Diaframma in gomma

- Valvola di Duckbill

- Freno della frizione magnetica

- Striscia di scanalatura sospesa

- Macchina da imballaggio >

- Macchina per cartone >

- Parti della macchina di cartone. >

- Cinture a doppia facciatura.

- Cucitura del sistema di incollaggio >

- Lama di taglio di cartone >

- Lama in acciaio di tungsteno >

- Mola

- Stripper di rifiuti

- Lama della macchina per imballaggio >

- Apparecchiatura pre-pressione >

-

Lama di taglio industriale >

- Lama da sega circolare di taglio delle piastrelle

- Lama della sega da taglio in metallo

- Lama segale da taglio in legno

- Lama segale da taglio del cibo

- Lama da taglio in fibra

- Blade di chipper

- Stampo pieghevole

- Lama per la macchina da taglio vegetale

- Lama sottile in acciaio

- Lama da stampo Tsukatani

- Lama da stampante

- Blade della macchina maschera

- Slitter Rewinder Blade

- Lama tmr

- Lama circolare del tabacco

- Roll Shear Blade

- Coltello dentellato per imballaggio

- Blade a fascia da taglio di carta

- Lame del dottore

- Lama rotonda

- Tre buche lama

- Lama ceramica

- Bastello a banda Blade per tessuto

- Bastello a banda Blade per spugna schiuma

- Bastello a banda per la scissione della macchina

- Lama del coltello a banda per carta

- Lama di taglio industriale

- Taglierina

- Smerigliatrice angolare

- Blade Shredder

- V Grooving Blade

- Forbici elettriche

- CNC Machine Blade & Tools

- Lama di trasformazione alimentare

- Notizia

- video

- Contatti

- Invia domanda