EnglishEspañolPortuguêsDeutschहिंदी日本語ខ្មែរNederlandsالعربية한국어मराठीMalagasyItalianoPolskiSvenskaελληνικάPусскийภาษาไทยTürkShqipMagyarViệtSamoaМонголMaltiIndonesia FrançaisMelayuҚазақшаYorùbáবাঙালিעִברִיתGàidhligSomaliEesti keelKreyòl Ayisyennorskčeštinaفارسیతెలుగుမြန်မာBosanskiMaoriქართულიRomânăбеларускіУкраїнськаతమిళGaeilgeSuomalainenپښتوລາວհայերենSlovenščinaFilipinoO'zbekÍslenskaייִדישLatviešuGalegoFryskनेपालीKurdîCatalàбългарскиHawaiianHrvatskiਪੰਜਾਬੀWong JawaKiswahililëtzebuergeschisiXhosaEuskalSundaZuluગુજરાતીТоҷикӣ

- Casa

- Chi siamo

-

Elenco prodotti

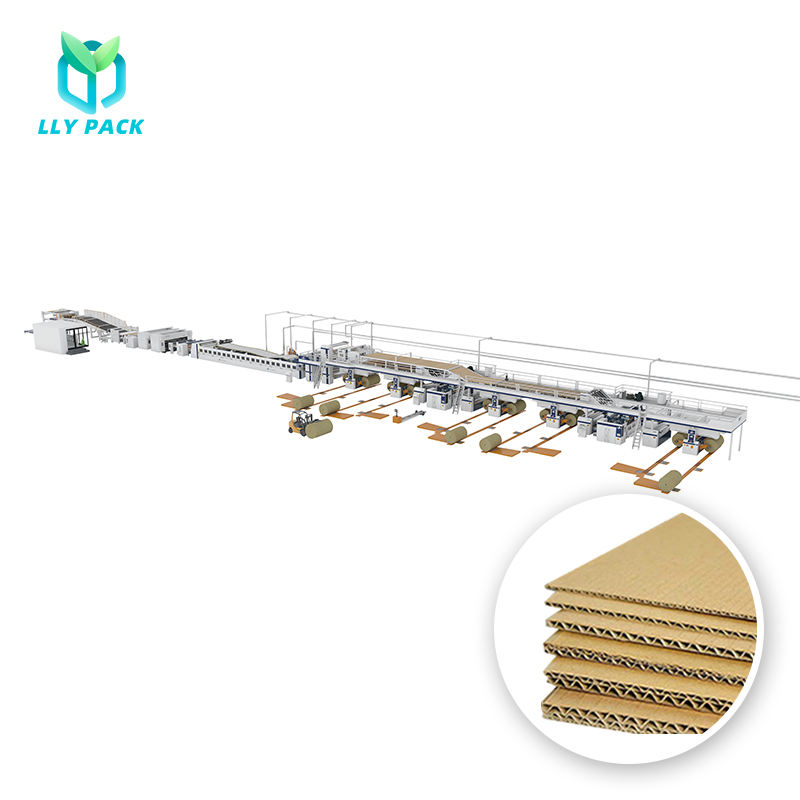

- Linea ondulata

- Macchina ondulata >

-

Ricambi a macchina ondulata >

- Giunto rotante

- Pettine per il marcatore di scivolone

- Pastiglie dei freni

- Pompa diaframma per colla

- Stripper di carta scarica

- Chuck di espansione

- Tubo flessibile in metallo

- Mola

- Nastro per splicer

- Rullo ondulato

- Lama di taglio

- Cintura di trazione del ponte sopraelevato

- Ruota del sole

- Cintura del trasportatore

- Lama da taglio NC

- Trappola a vapore

- Cilindri pneumatici

- Freno pneumatico

- Air Bellow Spring

- Pompa a vuoto ad anello d'acqua

- Lubrificante a macchina ondulata

- Distanziatore di gomma

- Distanziatore placcato in titanio

- Flexo Stampter Slotter

- Macchina della stampante Flexo >

-

Parti di ricambio della stampante >

- piastra di rame

- PIASTRA DI STAMPARE

- Pompa Aro.

- Pennello in acciaio e ottone

- Filtro in inchiostro

- Doctor Blades.

- Copertura dell'antico

- Lama di slotting.

- Nastro in fibra

- Cornice sospesa

- PET PRESSIONE PET con film

- Cuscino di stampa r e bak

- Ruota di alimentazione

- Un modo portante

- Die board rotary.

- Pompa a diaframma singola

- Blocco finale con condotto a inchiostro

- Diaframma in gomma

- Valvola di Duckbill

- Freno della frizione magnetica

- Striscia di scanalatura sospesa

- Macchina da imballaggio >

- Macchina per cartone >

- Parti della macchina di cartone. >

- Cinture a doppia facciatura.

- Cucitura del sistema di incollaggio >

- Lama di taglio di cartone >

- Lama in acciaio di tungsteno >

- Mola

- Stripper di rifiuti

- Lama della macchina per imballaggio >

- Apparecchiatura pre-pressione >

-

Lama di taglio industriale >

- Lama da sega circolare di taglio delle piastrelle

- Lama della sega da taglio in metallo

- Lama segale da taglio in legno

- Lama segale da taglio del cibo

- Lama da taglio in fibra

- Blade di chipper

- Stampo pieghevole

- Lama per la macchina da taglio vegetale

- Lama sottile in acciaio

- Lama da stampo Tsukatani

- Lama da stampante

- Blade della macchina maschera

- Slitter Rewinder Blade

- Lama tmr

- Lama circolare del tabacco

- Roll Shear Blade

- Coltello dentellato per imballaggio

- Blade a fascia da taglio di carta

- Lame del dottore

- Lama rotonda

- Tre buche lama

- Lama ceramica

- Bastello a banda Blade per tessuto

- Bastello a banda Blade per spugna schiuma

- Bastello a banda per la scissione della macchina

- Lama del coltello a banda per carta

- Porta della lama

- Lama di taglio industriale

- Taglierina

- Smerigliatrice angolare

- Blade Shredder

- V Grooving Blade

- Forbici elettriche

- CNC Machine Blade & Tools

- Lama di trasformazione alimentare

- Notizia

- video

- Contatti

- Invia domanda